CMP Filter specializes in the retrofit of ANY type of grinding filter including central systems.

Your Source For The Largest Magnetic Drum Separators On The Market

Solid ceramic or “rare earth” no leak magnetic drum construction.

Large Diameter Magnets - Up To 1,300 Lbs Per Separator - Capable Of Removing Massive Amounts Of Metal

Large Diameter Magnets, Industries Largest Drum Mass. We build The Big Ones

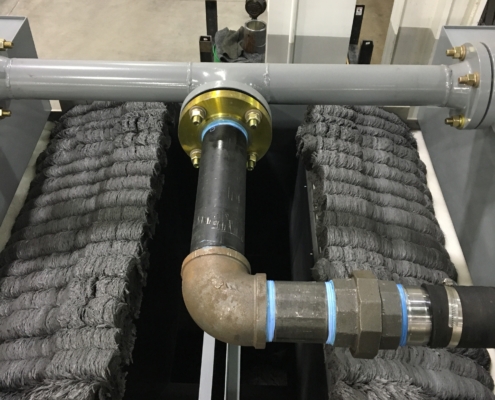

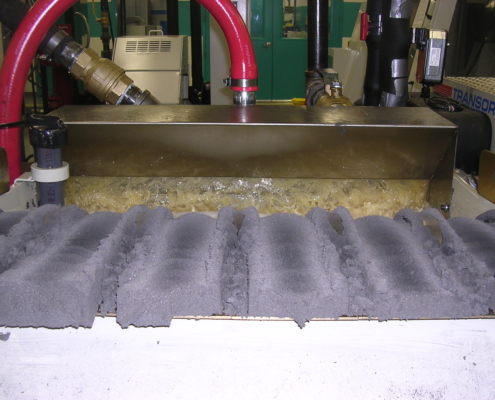

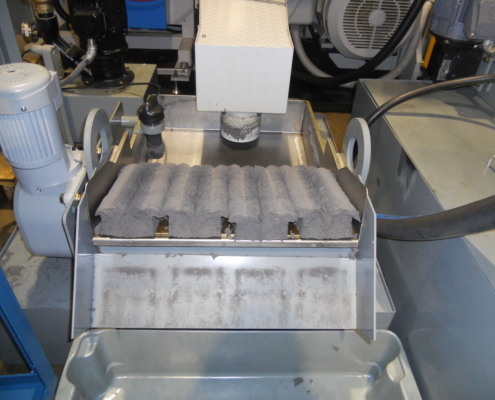

Twin Opposed Rare Earth Separators - Centerless Abrasive Belt Grinding Line

Retrofit Existing High Volume Filter Tanks Saving Tens Of Thousands in Replacement Costs.

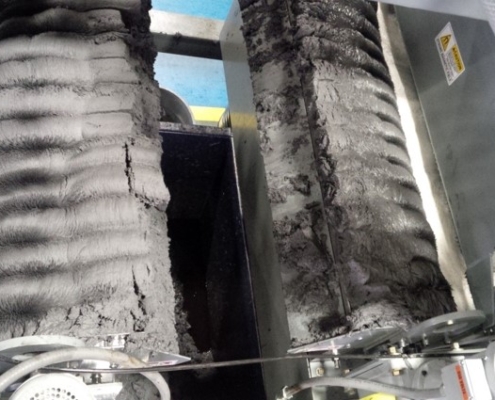

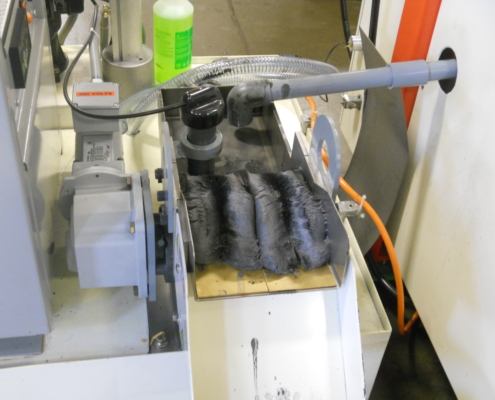

Remove Low Mass Creep Feed Grinding Swarf - "Rare Earth" Magnetic Separator

Powerful “Rare Earth” Magnets Remove Low Mass Floating Swarf – 50-75% Paper Savings – Lower Direct Maintenance

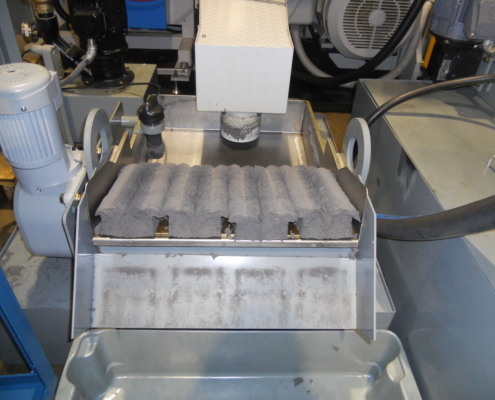

Twin 130 GPM Rare Earth Magnetic Coolant Separators

Centerless Abrasive Belt Grinding Line

Rare Earth Magnetic Separation - Superior Particle Capture Coupled With Dry Sludge Discharge

Ideal first stage metal removal solution for heavy stock removal grinding operations – abrasive belt, cylindrical work rolls, centerless, double-disc, etc.

130 GPM Rare Earth "Indexing Drum" Magnetic Separator

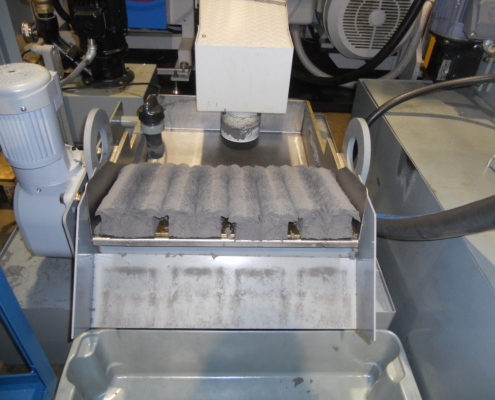

Retrofit of Vacuum Paper Filter – Powdered Metal – Dry Sludge

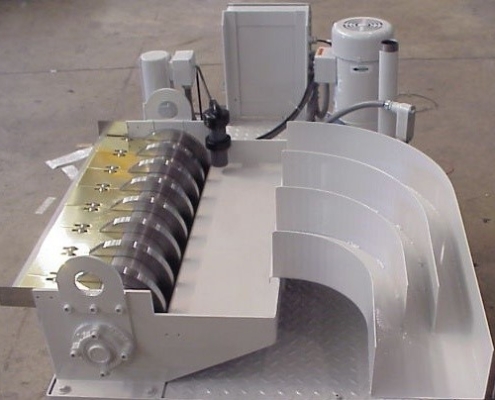

300 GPM "Indexing Drum" Magnetic Coolant Separator

Simultaneous Powdered Metal Grinding & Machining – 300 GPM

"Rare Earth" Magnetic Separator

400 Grade Stainless Steel – Significant Polishing Cartridge and Direct Maintenance Savings

150 GPM Rare Earth Coolant Separator - 95-97% Metal Removal

Unmatched pre-filtration ahead of cyclonic separators, vacuum, or high pressure media filters. Longer cycle times, less media used.

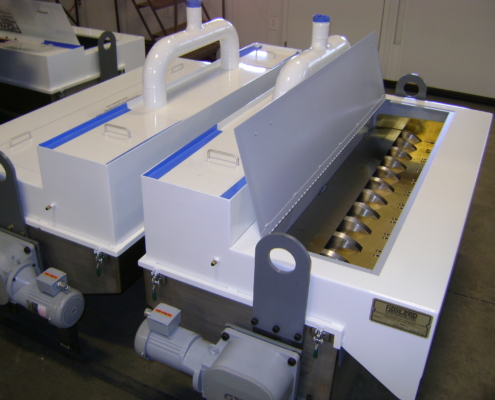

Keep Old Central Filters Running Longer, Costing Less

Up Dating 17 Year Old Central Grinding System – Paper Index Cycle Goes From 1 Hour To 4 Hours – Improved Cleanliness – Lower Maintenance

Double-Disc Grinder - "Rare Earth" Separator

95% Metal Removal Before Paper Media – 50-75% Paper Savings

First Stage Rate Earth Magnetic Separaator

Unmatched metal removal ahead of ANY type media polishing filter – paper bed, cartridge, bag, vacuum paper.

Honing - "Rare Earth" Magnetic Separator

Superior 1st Stage Honing Separation – Unmatched Polishing Filter Results – Lowers All Downstream Costs

Fine Grinding & Super Finishing

Unmatched First Stage Removal Of 5-15 Micron Particles – Superior Cartridge Life

Contact us for prompt detailed proposals.

Office: (630) 858-3020

Mobile: (630) 886-7136

E-Mail: cmpfilter@gmail.com

CMP Filter is your source for large ferrite and “rare earth” magnetic separators to meet any high production grinding or machining need.

We Build The Big Ones – Handle Hundreds of GPM

- Totally reliable first stage metal removal

- Eliminate floating or settling swarf

- First stage cleanliness down to 10-15 micron

- Cut media or cartridge consumption

- Improve coolant life

- Reduce direct tank maintenance

Use with ANY downstream polishing filter design:

- Drag-Out Settling Tank

- Vacuum Paper Filter

- Paper Bed Filter

- Cartridge Filter

- Cyclonic Separator

- High Pressure Clam Shell Filter

- Back-Wash Tubular Filter

- Centrifuge

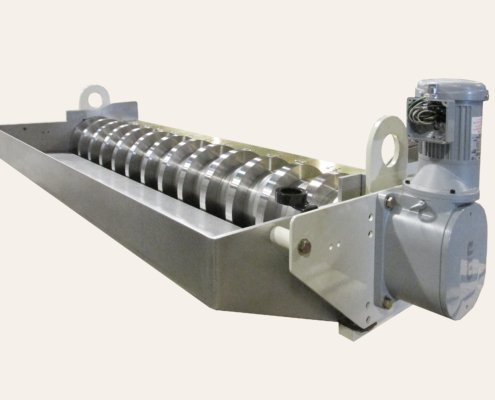

Magnetic Coolant Separator - 300 GPM

Large ferrite and “rare earth” magnetic coolant separators – capacities to 300 GPM per separator – handle higher flows with multiple units

Magnetic Coolant Separator - 200 GPM

Handles either ferrous swarf or broken ferrous chips & fines – filters out grinding size particles and broken chips in ONE STEP

130 GPM Magnetic Coolant Separator

Large magnets and concentrated mass Handle ANY sludge volume

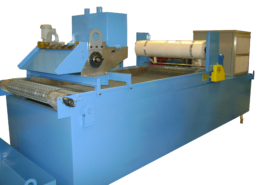

Magnetic/Paper Bed/Chiller System - 90 GPM Heavy Stock Grinding

System designs for double-disc, centerless, cyclindrical roll grinders, etc.

Ferrite Magnetic Coolant Separator - 70 GPM

Mounted to 24 sq ft paper bed filter

Magnetic Coolant Separator - 50 GPM

Maximum magnetic surface and mass presented to coolant flow for superior coolant filtration results.

Rare Earth Separator/Paper Bed Filter/Chiller - 10-15 um first stage separation efficiency.

Rare Earth Magnetic Oil Separator - Cutter Tool Grinding

Note dry, oil free sludge discharge – maximum metal removal in front of cartridge or backwash filters.

"Rare Earth" Magnetic Separator - 60 GMP

Mounted to transfer tank – pumps 10-15 micron nominal semi-clean coolant to paper bed filter.

Heavy-Duty "Rare Earth" Magnetic Coolant Separator - Centerless Shaft Grinding

Paper consumption, coolant life, tank and chiller maintenance significantly reduced.

Magnetic Coolant Transfer Tank - 40 GPM

Magnetic Coolant Separator –

ferrite separator pumps 20-30 micron semi-clean coolant to paper bed filter.

Magnetic Coolant Separator - 15 GPM

Quality You Can See – 20 year+ service life

Rare Earth Honing Oil Separator - 10-15 micron first stage metal removal efficiency

Contact us for prompt detailed proposals.

Office: (630) 858-3020

Mobile: (630) 886-7136

E-Mail: cmpfilter@gmail.com

Magnetic Coolant Separators – Ferrite or “Rare Earth” Magnets

The industry’s largest capacity and highest strength magnetic separators for grinding, honing, polishing, and broken machining chips.

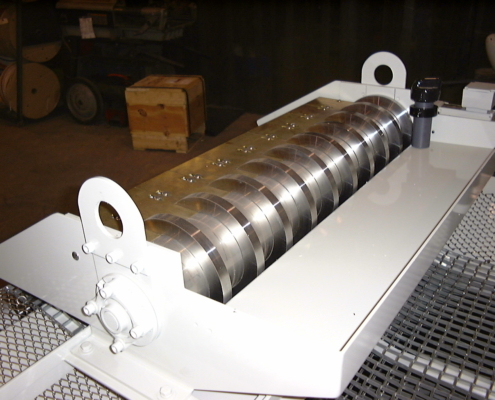

Quality features include solid drums, heavy-duty sealed for life bearings, and the largest magnetic mass and surface area per GPM of flow in the industry. Unique “indexing drum control” results in superior particle separation and DRY sludge discharge.

NEW “Rare Earth” Neodymium Iron Boron Separators have magnets 10 X more powerful and provide consistent 10-15 micron particle removal with M2, HSS, 400 grade S.S., heat treated steel, cast or ductile iron, and powdered metal.

“Rare Earth” pre-separation improves part quality and ALL downstream process costs are lowered – media, coolant, wheel life, tooling, and tank maintenance.

New “Universal” Magnetic Transfer Tanks can be coupled to ANY machine or filter ensuring the best part quality and lowest filtration cost.

- Simple, low maintenance design

- Demo units available to prove out applications

- Design capabilities to handle high flow and stock removal applications

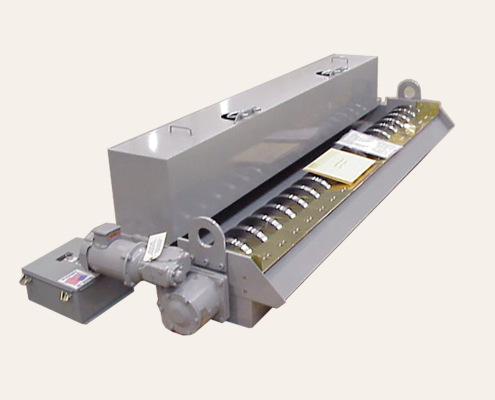

Magnetic Coolant Separator - Chips

Deep Hole Gun Drill – Oil

Remove chips & particles in ONE STEP

Magnetic Coolant Separator - Chips

Helical Broach – Twin Spindle

Dual Units handle 200 GPM of 400 SSU oil

Magnetic Coolant Separator - Chips

Helical Broach – ONE STEP removal of chips & 20 micron particles.

Magnetic Coolant Separatoar - Chips

TBT Deep Hole Gun Drill – Coolant

Remove chips & particles in ONE STEP

Magnetic Coolant Separator - Chips

Horizontal Broach – handle ANY chip load – 20 year+ service life.

Magnetic Coolant Separator - Chips

Ideal for gear machining – minimal oil loss

"Indexing" Drum Control

Better separation – cleaner coolant – drier chips

Turning Cell Filter Tank - 200 GPM

Compact design – handle 4-6 turning machines

Turning Cell - Ductile Iron

Vortex pumps – chips and coolant pumped overhead

Turning Cell - Ductile Iron

Ideal for ductile iron machining – handle any chip volume

Contact us for prompt detailed proposals.

Office: (630) 858-3020

Mobile: (630) 886-7136

E-Mail: cmpfilter@gmail.com

CMP Filter offers unique magnetic “chip” separators for ferrous broken chip CNC machining operations. Large diameter ferrite magnets present a massive magnetic mass to the machining coolant or oil flow. Outperforms any conventional chip conveyor.

Broken chips AND 20-30 micron size particles are removed in ONE STEP. “Indexing” drum control automatically discharges any volume of chips while minimizing coolant or oil loss.

Magnetic “chip” separators are ideal for any steel gear machines – helical broaches, gun drills, gear shavers, etc. – or cast iron and ductile machining chips.

First stage 20-30 micron coolant or oil cleanliness outperforms any mechanical or magnetic conveyor or gravity back-wash screen.

Step outside the box and find out how magnetic “chip” separators can make your gear machines run better.

CMP Filter Company

Contact Information

Lawrence M. Sweeney, President

Office: (630) 858-3020

Cell: (630) 886-7136

E-Mail: cmpfilter@gmail.com